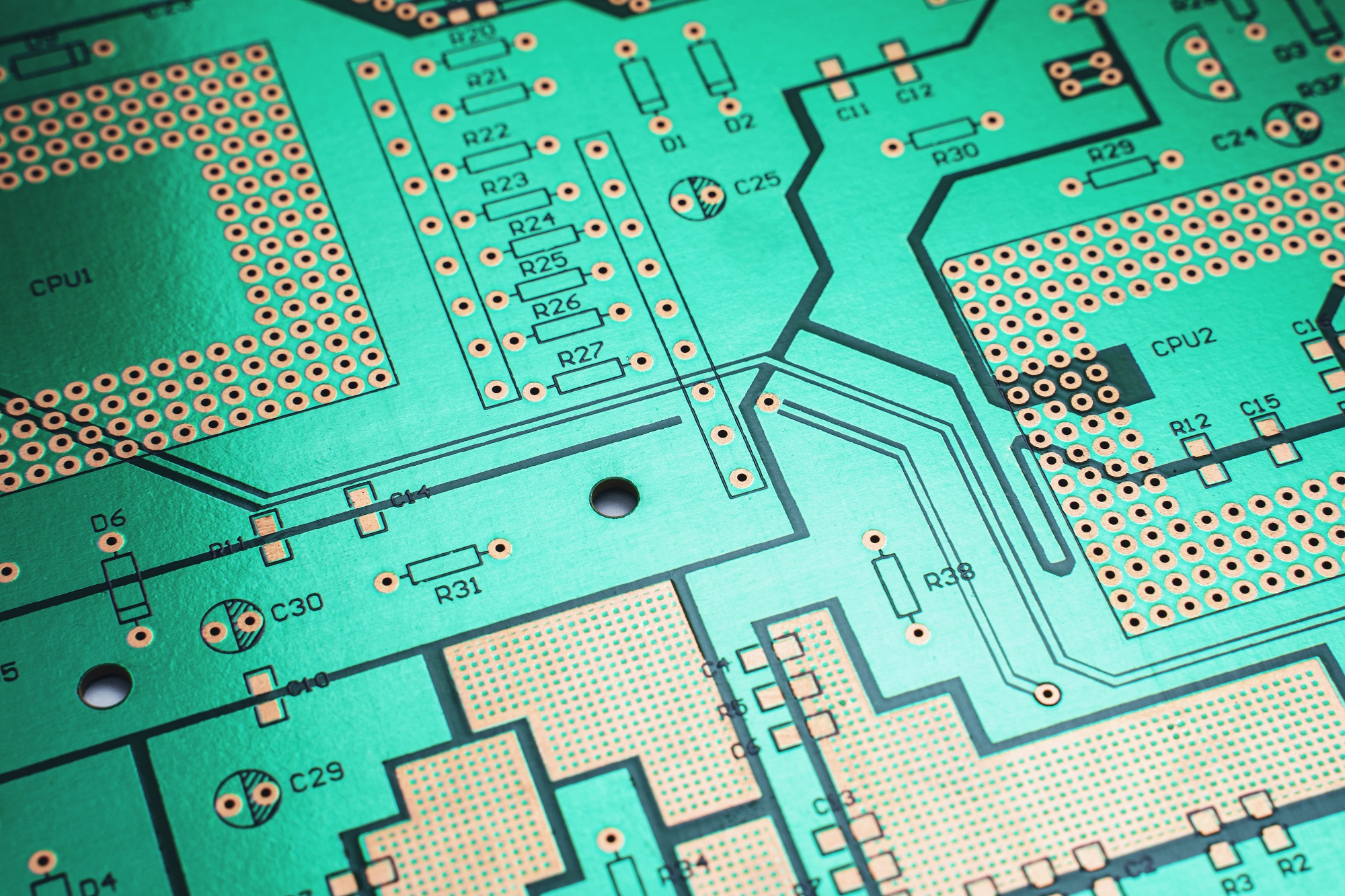

What is a PCB Prototype?

PCB prototyping is vital for testing and refining electronic circuits before mass production, ensuring performance and feasibility using methods like etching, milling, and 3D printing.

PCB (Printed Circuit Board) prototype is an important step in the design and fabrication of electronic circuits. Before mass production, PCB prototypes provide an essential platform for testing and evaluation. PCBs, the less-known heroes of countless electronic devices, form the backbone of modern electronic circuits, bearing the responsibility of circuit connection and component layout.

Creating a PCB prototype starts with the meticulous crafting of a schematic diagram, meticulously outlining the intricate connections between components. Like an architectural blueprint, it lays the foundation for the physical layout. Following that, a thorough placement dance takes place, with components and connecting paths carefully placed on a real board. Finally, specialized procedures such as etching or milling bring the design to life on the circuit board.

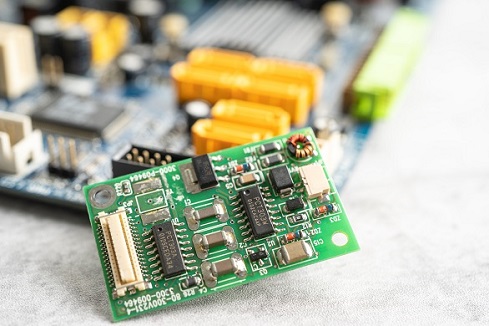

However, the true value of a PCB prototype extends beyond its fabrication. It serves as a testing arena where the design undergoes rigorous inspection. Functionality and performance are carefully evaluated, allowing designers to detect and correct any underlying defects or flaws in the circuit. This proactive approach ensures optimal performance before mass production.

The advantages extend beyond only testing. PCB prototypes enable designers to test the very feasibility of their creations. This is especially important for complicated electronic gadgets. Designers can reduce the risk of costly errors and production delays caused by a poor design that is sent directly to mass production by building a workable prototype. Consider it a critical checkpoint that ensures a smooth transition from the design concept to a perfectly functioning electronic marvel.

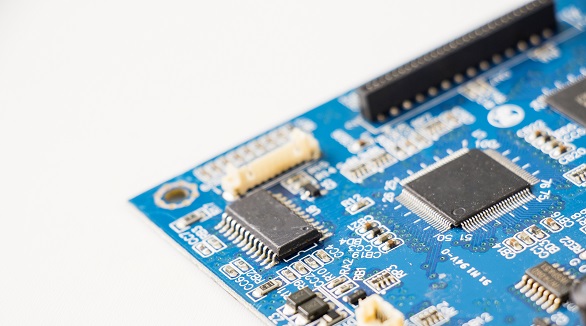

Several methods for creating PCB prototypes, each with its advantages. Let's explore some of the most common:

- Etching: This traditional method transfers the circuit pattern onto a copper-clad board and removes unwanted copper.

- Milling: A CNC milling machine precisely removes unwanted copper, leaving behind the desired circuit pattern.

- 3D Printing: This cutting-edge method utilizes a 3D printer to create a physical model of the PCB, including conductive traces.

- Breadboarding: For simpler circuits, breadboarding offers a quick and easy way to prototype using a pre-built board with connection points.

In conclusion, PCB prototyping is an essential step in the design and production process, allowing designers to refine their ideas, identify potential problems, and ensure a smooth transition to mass production, ultimately leading to a more reliable and successful electronic device.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Creating PCB prototypes before full production avoids potential failures, saves costs, and ensures quality. PCBX offers rapid, accurate prototyping for efficient testing and design validation.

Creating a prototype PCB is essential to verify your design's functionality before full production. PCBX provides timely, cost-effective prototypes, allowing flaw detection and multiple design tests. Prepare your design specs, run prototypes, and smoothly transition to mass production.

Prototyping PCBs is crucial for all designers and costs vary based on factors like board size, material, complexity, and urgency. Prices range from a few dollars to hundreds. Smaller batches cost more per unit.